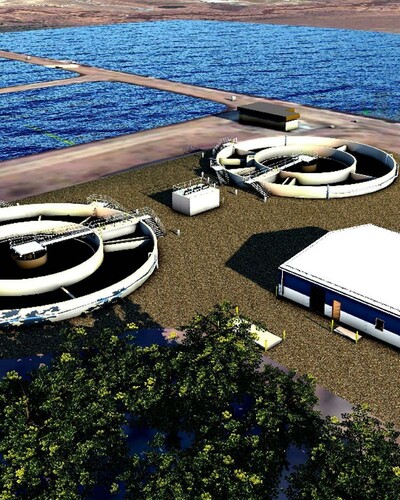

The Town of Edson is the provider of Water and Sewer services for the community.

Edson uses a well system and we are constantly exploring new sites to ensure our supply of fresh water is maintained and that the water collected is of the highest quality.

Forms

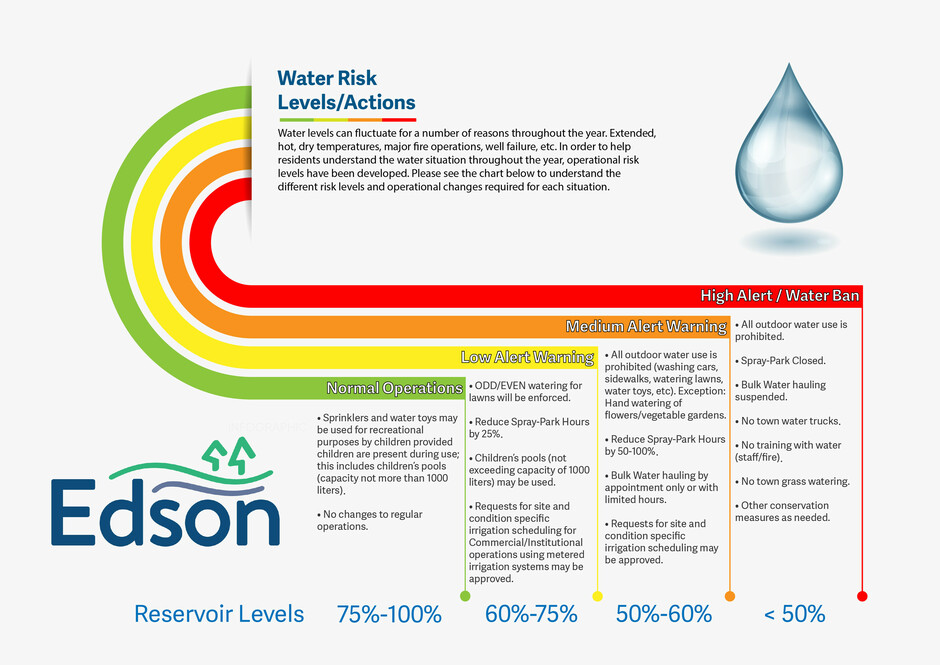

Water Risk Levels

The Town of Edson's water supply comes from a well system. Currently we have 11 wells, with 9 of them actively supplying water.

The water is treated before entering the potable system. A 12% sodium hypochlorite liquid solution is used, along with disinfection piping, to achieve a 4-log virus removal rate.

Some of the advantages of a well system:

- wells are considered high quality and require minimal treatment to meet Canadian drinking water guidelines

- maintenance costs are low

- more than one well source

- economical building costs

- wells are located close to existing distribution lines.

Some disadvantages are supply volumes are lower compared to a river, wells are spread out around the Town, there are multiple pumps and buildings to maintain, and wells require constant exploration.

While we do draw water from the aquifer, the environmental benefits to a well system are the reduction in chemicals for treatment and a reduction in power consumption compared to traditional treatment facilities along the river.

Edson’s water meets and exceeds all provincial and national standards for safe, clean drinking water, both at the new Water Treatment Plant, wells, and through the distribution network that transports treated water to your home or business.

There have been a few inquiries following recent media reports about asbestos-cement (A-C) water pipes. The following information about Edson’s water system has been gathered by our Public Works Department.

Edson’s water system consists of around 700 water main valves and 2700 service connection valves. Being able to operate these valves at a moment notice is extremely important. In an emergency, sections of the distribution system may need to be shut down without delay. However, if a valve is not used over a period of time it can seize up from corrosion and get stuck or break, making it inoperable.

Steps in Valve Exercising Program

- Locate Valves

- Find valves in a systematic approach by visuals, metal detector, maps, as-built, repair reports.

- Raise or repair valve caps/risers.

- Valves that are not located are to be recorded and corrected.

- Valves are to be marked with blue paint and/or blue flags.

- Exercise Valves

- Locate Valve.

- Clean out Valve box or CC.

- Exercise valve through a slow opening and close. Ensuring valve completely opens and closes. Ensuring valve operates freely with little resistance.

- Record all information.

- Record Information

- Location.

- Number of turns.

- Size of valve and depth.

- Operating condition.

- Maintenance history (Dates, previous work).

- Open Direction.

- Update information on Asset manager/Valve Sheets.

- Schedule and perform needed repairs

- Critical condition valves are prioritized.

- Record keeping will help with budgeting and planning.

Unclear on Town vs Owner responsibilities? See the chart below.